DRUM SEQUENCERS

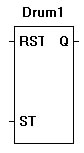

| Drum Sequencer |  |

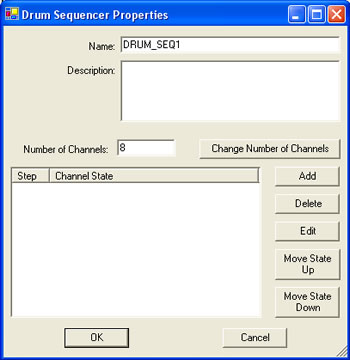

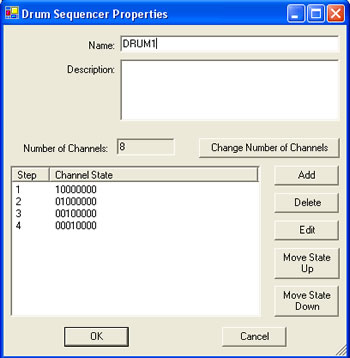

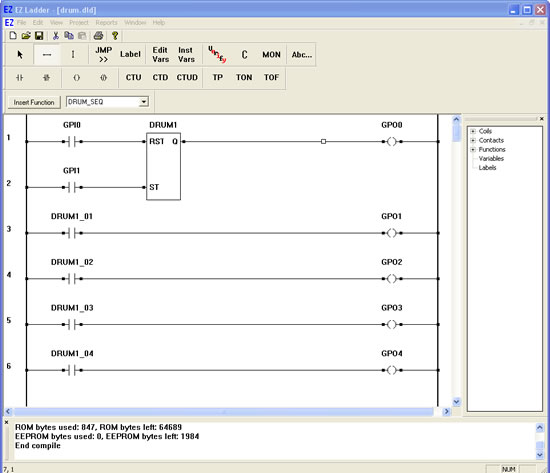

| The DRUM_SEQ function steps through a pre-programmed set of on/off channel (contact) settings when the ST input is pulsed. The drum sequence is programmed with a maximum of 32 channels. Each channel may be programmed to be on or off (1 or 0) for each step. When the ST input is pulsed, the drum sequencer increments to the next step and the channel’s contacts change to the appropriate state.

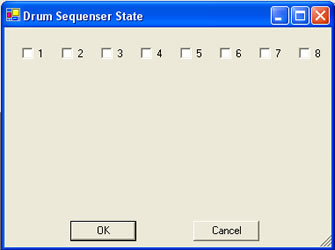

Each channel is designed to represent a contact. When the channel is set to 0 (off), its contact is false. When the channel is set to 1 (on), its contact is true. The contacts are automatically named according to the DRUM_SEQ name. The channel settings are defined in a matrix. For each step in the drum sequencer, using the check box, select the state of each channel for each drum sequencer step. |

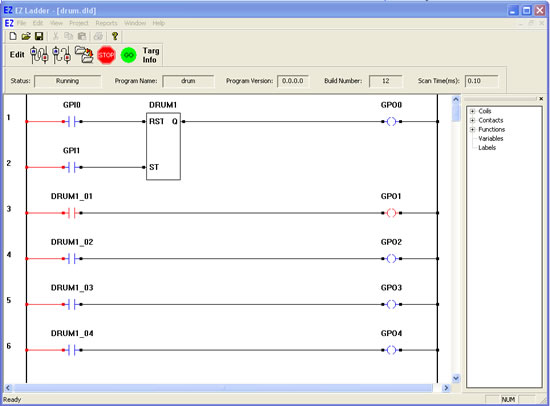

You have completed the Drum Sequencer exercise.