COUNTERS

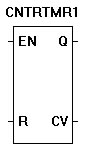

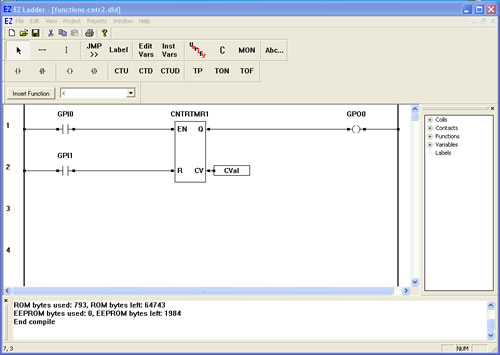

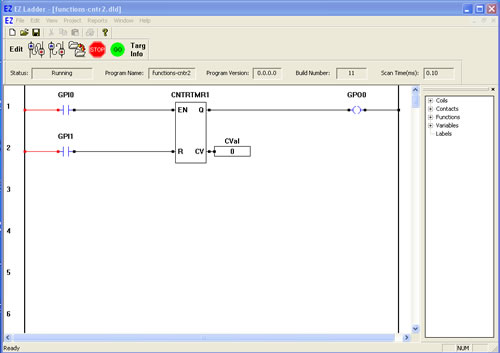

| CNTRTMR - Hardware Counter / Timer |  |

| The CNTRTMR function provides access and functionality to a hardware timer or counter (must be supported by target).

When configured as a counter, the the trigger can be set to rising or falling edge of the input pulse on the EN input. R resets the current counter value (CV). Q is true when the counter is counting. When configured as a timer, the trigger may bes set to rising, falling or any edge of the input pulse on the EN input. R resets the current timer value (CV). Q is true when the timer is counting. The timer resolution is .042 microseconds. |

You have completed the CNTRTMR exercise.