COUNTERS

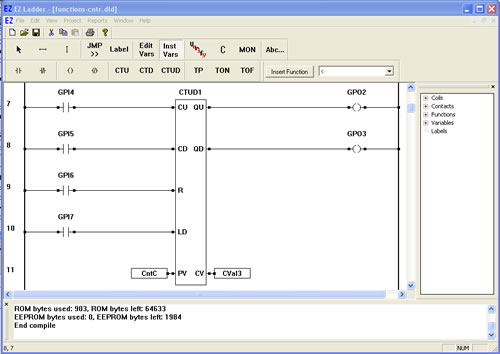

| CTUD- Up and Down Counter |  |

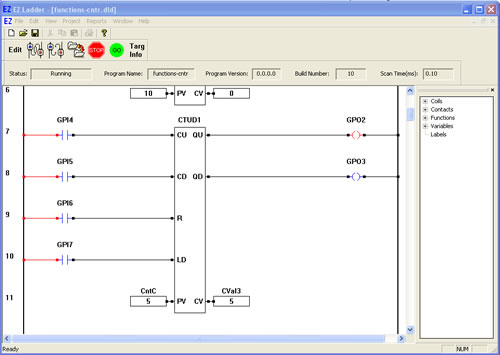

| The CTUD function is programmable up/down counter. With reset (R) not active, a true on input (CU) will increment the current (CV) count by one, while a true on input (CD) will cause the current count (CV) to decrement by one. When the CV = PV, the output (QU) will be true. When the CV = 0, the output (QD) will be true. A true on the reset (R) will cause CV = 0, QU to go false and QD to go true. A true on the load (LD) will cause CV = PV, QU to go true and QD to go false. The reset (R) is dominant and takes priority over all inputs. The counter inputs trigger on a false to true transition on CU or CD. |

You have completed the CTUD exercise.