BIT MANIPULATION

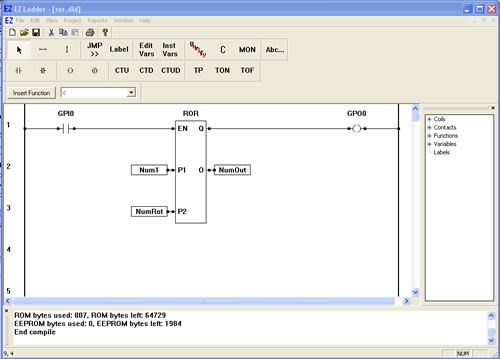

| ROR - Rotate Bit Right |  |

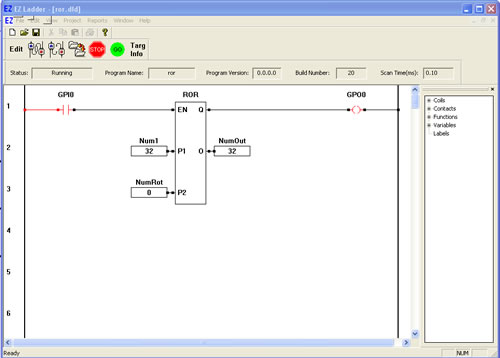

The ROR function provides a right-bit rotation of the P1 input. P2 specifies the number of one-bit rotations. The P1 number is a integer representation of a binary number. The P2 number is an integer representation of the number of binary rotations (shifts) to occur to P1. The actual bit only rotates when the minimum number is reached (example: 32 bit rotation to the input number 32). The enable (EN) must be true for the ROR function to be enabled. The Q output is true when the ROR function is enabled. The O Output is the rotated number (represented in integer form). |

You have completed the ROR exercise.